First Flush Diversion Systems

Underground first flush system

First flush Systems (Also referred to as underground first flush systems, or first flush diverters) help prevent contaminants that would otherwise enter the stormwater network during rain activity by ‘flushing’ a pre-specified volume of initial water runoff (calculated in relation to the area that runoff occurs) to a designated trade waste outlet for treatment, or storage before remaining runoff can enter the stormwater network. They are completely automated and highly effective, helping you avoid fines or potential shutdowns.

| Material | 6mm medium-density polyethylene(MDPE) |

| Silt basket capacity | 50 Litres / 9mm holes |

| Diversion valve flow rate |

1200L/min @.5 head |

| Grate | Class B heavy duty galvanised |

| Material | 6mm Medium-density polyethylene(MDPE) |

| Silt basket capacity | 50 Litres / 9mm holes |

| Diversion valve flow rate |

1200L/min @.5 head |

| Grate | Class B heavy duty galvanised |

| Stormwater quality improvement device material | 6mm Medium-density polyethylene(MDPE) |

| Cover plate | 6mm tread plate |

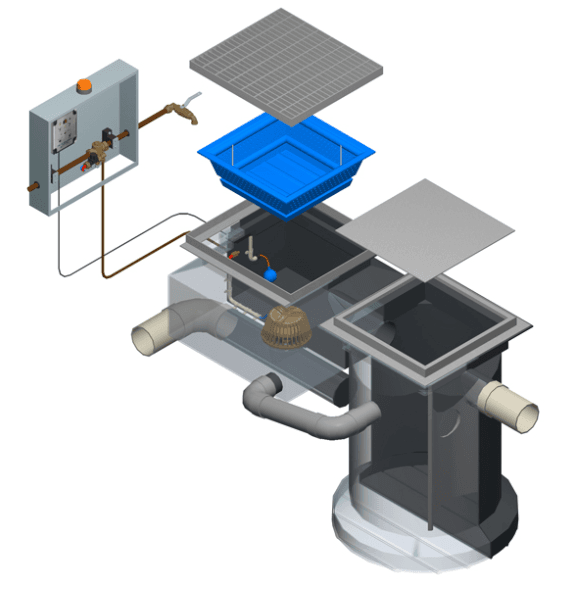

Differences between the TWFF600 and TWFF600BRT first flush diversion systems

The TWFF600 is our standard First Flush System and transports the initial ‘First Flush of contaminated water through the trade waste outlet for treatment.

The TWFF600BRT is similar to the TWFF600 in operation however the system contains a secondary chamber (stormwater quality improvement device) that includes a baffled outlet. After the initial first flush activity, any remaining contaminants that float to the surface when entering the stormwater outlet e.g. Hydrocarbons and other floating debris are trapped in the secondary chamber due to the baffled design of the second chamber.

About underground first flush systems

Standard usage:

- Wash bays

- Workshops and factories

- Airports

- Construction sites

- Fuel stations or refueling stations

Generally speaking most businesses, especially those that have a requirement to wash down vehicles and machinery or have large open unroofed areas, run the risk of fuel, oil and other pollutants being ‘flushed’ into the stormwater network during the initial stages of rain activity due to contaminants residing on the surface after site-specific activity has taken place.

A First Flush system, however, redirects the initial ‘First Flush’ of contaminated water via the trade waste outlet to an appropriate holding tank and from there, to the desired treatment systems e.g. Oil and Water Separator or a Recycling and Re-use Systems.

As most contaminants are dislodged during the initial phase of a rain event this greatly reduces the impact of pollutants entering the stormwater network and helps ensure your business operates in an environmentally compliant manner.

During normal wash down activity

When incorporated into an existing wash down area the system will detect normal wash down activity, diverting all water runoff to either a treatment system or holding tank via the trade waste outlet.

Once the wash down activity is complete the valve returns to a closed position. It is then re-opened after a 5-minute delay to ensure all drainage from the wash down area is diverted.

During rain activity

When not being utilised for wash down the system is essentially on standby and will detect rain activity and ‘flush’ a pre-specified volume for treatment before allowing the remaining run-off to enter the stormwater network.

The system also takes into account the total volume of rain activity, which is useful in the case of intermittent rain which builds up over time along with heavier ran activity such as during a thunderstorm.

First flush systems have a small footprint, suit most wash down areas, require very little maintenance or additional consumables and are a cost-effective way to ensure your business is environmentally compliant.

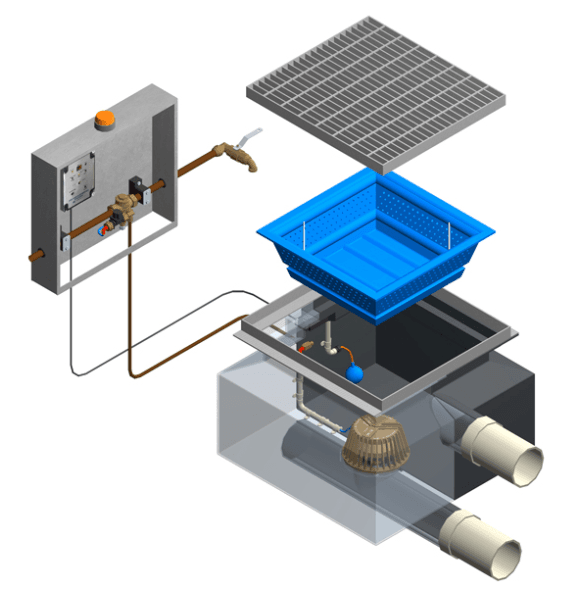

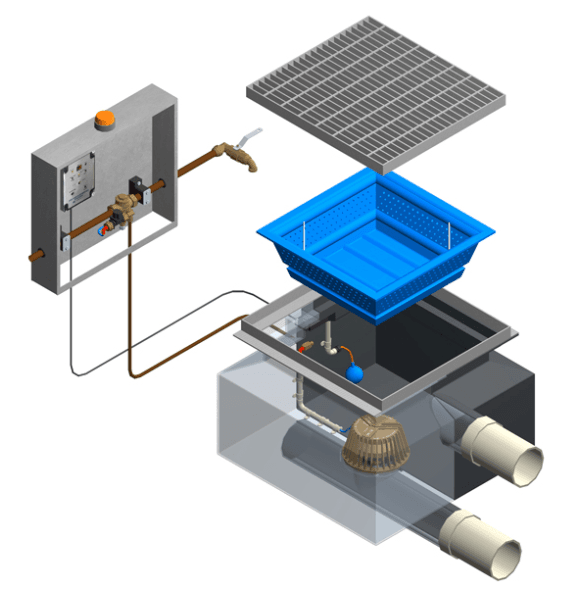

First flush system design

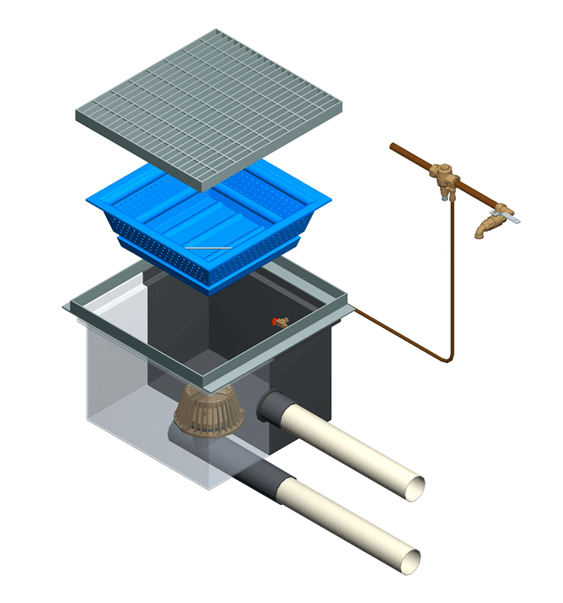

The first flush system consists of the following components:

- Polyethylene chamber with a 600 square medium duty grate

- Removeable Polyethylene silt basket (50 litre capacity) with galvanised grate

- Demand Valve

- Stainless Steel Panel (containing all electrical control equipment)

- Diversion Valve

- 150mm outlet to stormwater

- 150mm outlet to Trade Waste (sewer network via treatment system)

- Float mechanism

- Strobe alarm (optional)

- Baffled Stormwater quality improvement device (TW600BRT only)

*225m Stormwater outlet also available

*Standard class ‘D’ grates on all systems

How does a first flush system work?

During normal washdown activity, the diversion valve is held in an open position, allowing all water runoff to be diverted from the bottom the chamber via the trade waste outlet.

During a rain event, water runoff enters the First Flush System via the Galvanised grate, before entering the removeable silt basket. Larger particles and contaminants are caught in the silt basket which consists of 9mm holes and can be manually removed.

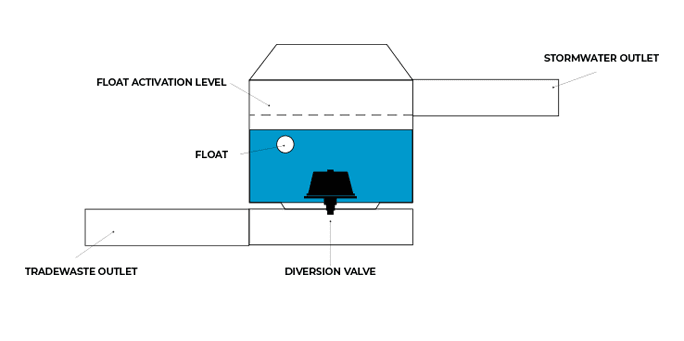

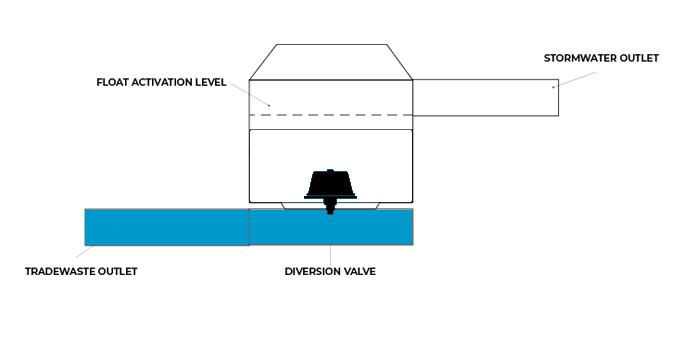

During a rain event, the First Flush system reacts to rain activity by detecting the water level within the First Flush System. It does this by utilising a float mechansim that upon reaching the float activation level activates the diversion valve at the bottom of the chamber by sending a signal via the ½” copper drive line that activates the diversion of contaminated water, releasing this initial ‘first flush’ to the trade waste outlet for treatment or storage.

The TW600BRT works almost identically with the exception that after the initial first flush it can also trap any minor quantities of floating debris such as Hydrocarbons that float on the surface due to being a lower density than water.

In the diagram above, the water is filling the chamber of the First Flush System as the water level sits below the activation level.

The diagram above shows the diversion valve being activated once the float has reached the activation level, allowing the water to be released to the lower chamber where it is transported via the trade waste outlet.

First flush diverter calculation

A First Flush Diverter must divert what is deemed to be a safe amount of water run-off before ceasing to divert the runoff to the tradewaste valve. To establish the amount specific to your site the following equation is required.

Meters squared X pollution factor = Litres to be diverted

This essentially means the total surface area e.g. surface of washbay for the First Flush System captures water runoff from calculated by the level of pollution associated with the area resulting in the correct amount of wastewater runoff to divert.

Pollution factor

| Minimal Pollution (small amount of potential contaminants) | 10mm |

| Moderate to Heavy Pollution (moderate to high amount of contaminants) | 20mm |

*Subject to council regulations and guidelines.

* As an example, a 10m X 10M concrete wash bay in a minimal polluted environment would require the first 10mm of rain diverted.